How are structural pellets manufactured?

The Premos 5000 can process the pellets directly in the field or even outside in a stationary position after harvesting. Thanks to these flexible application options, the machine can be optimally utilised throughout the year.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Produced directly on the field

As the first mobile pellet press, the Premos picks up stalk-type crops, such as straw, hay or alfalfa, directly via the pick-up in the field where it compresses them into structural pellets.

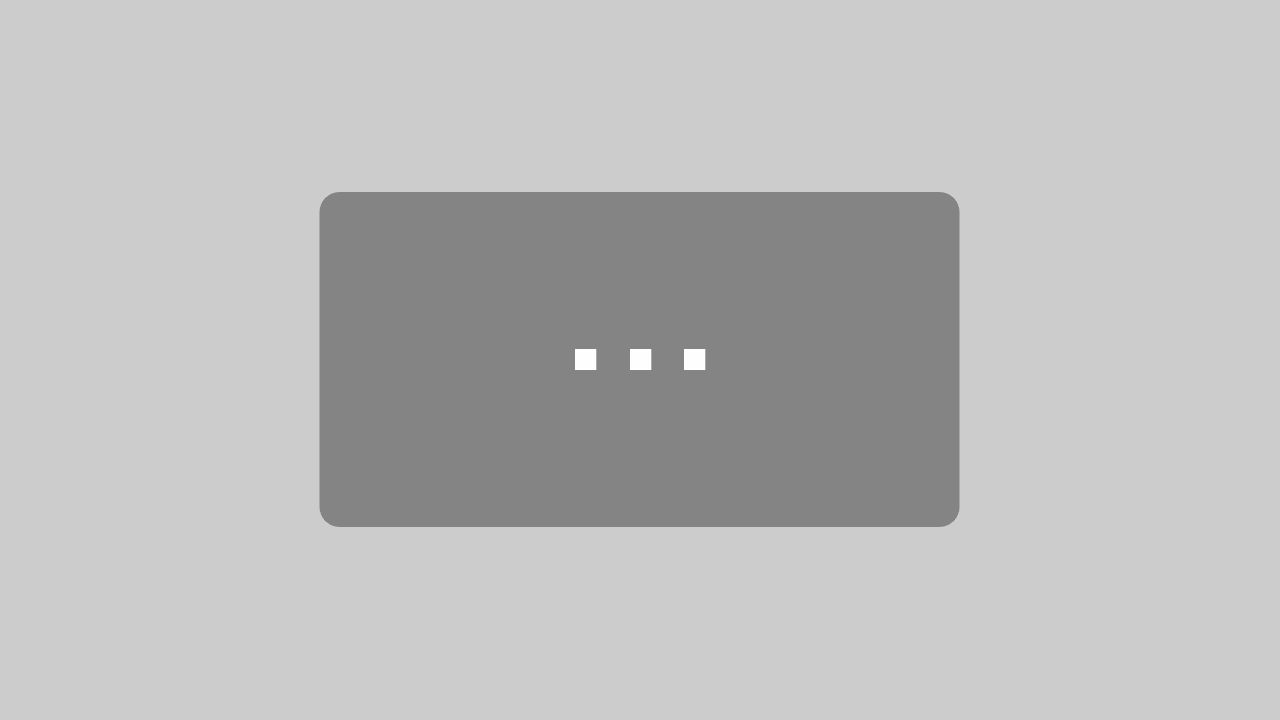

In stationary operation, the pick-up is replaced with a bale shredding system. This breaks up the baled crops and doses them evenly into the pelleting machine.

Off to the baler: The loose crops are fed into a feed channel via a feed rotor where stones and other impurities are removed with the aid of an upstream trough. A conveyor belt then transports the crops to the pellet press rollers where the crops are finally pelletised.

The manufacturing process

Rollers and balers

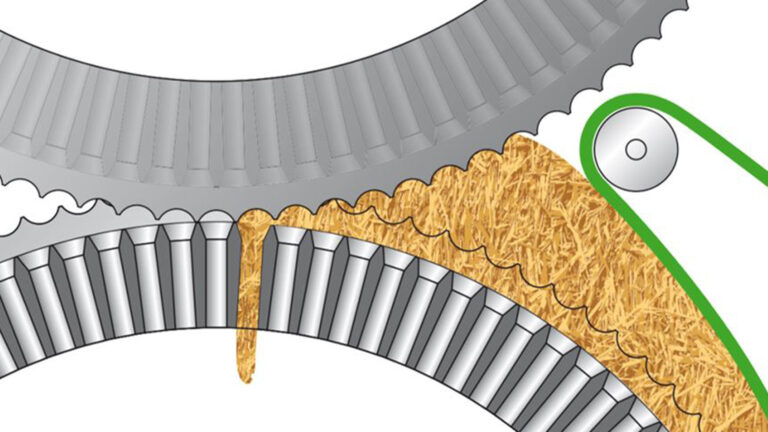

The unground crops pass between two counter-rotating and intermeshing pellet press rollers which are equipped with alternating rows of toothed and perforated dies. The teeth of one roller seal the channels of the perforated dies of the other roller and push the material through the channels of the perforated die. Pressures of up to 2000 bar and temperatures of 70 to 90 °C are generated.

Adjusting the pellet length

Sieving out fine particles

Inside the rollers, augers convey the pellets to the elevator which feeds them through a rotating sieve for dedusting. Fine particles, which fall through the sieve, are fed back to the pellet press rollers. This produces optimum quality pellets which are ideal for material or energy use.

Storing and transferring pellets

Contact

Do you have any further questions and would like to contact us? The contact form is the easiest way.